Chinese Scientists Develop Greener Method to Produce Propylene

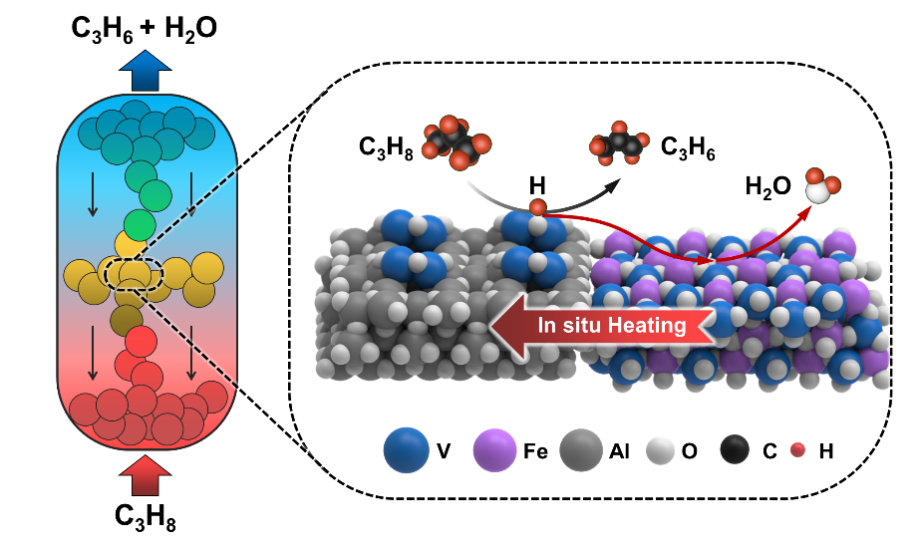

Propylene production by coupling propane dehydrogenation with selective hydrogen combustion.?(Photo?provided?by?Tianjin University)

By?CHEN?Xi?&?ZHAO?Hui

A research team from China's Tianjin University has developed a groundbreaking method to produce propylene, a colorless hydrocarbon gas, with reduced emissions. This is a boost to advancing sustainable and environmentally friendly practices in the petrochemical industry. The findings were published online in the journal Science on July 28.

Propylene plays a pivotal role in the global petrochemical industry chain. It serves as a fundamental chemical feedstock for various downstream products, including plastics, medical supplies, automotive components and building materials. China currently has the highest demand for propylene and is also its biggest producer globally. However, the existing technology for the production of propylene from propane requires substantial heat, which means high energy consumption and carbon emissions. Additionally, the domestic petrochemical industry's heavy reliance on imports poses a challenge.

Currently, propylene production accounts for approximately eight percent of China's carbon emissions and five percent of the global petrochemical industry's. Efforts are being made to develop sustainable alternatives that reduce emissions while meeting the increasing demand for propylene both domestically and internationally.

Led by Prof. Gong Jinlong, the energy and catalysis adventure team at Tianjin University developed a reaction system comprising metal oxides for the dehydrogenation of propane. The system efficiently utilizes the heat generated through its selective combustion of the side product to compensate the heat needed for the overall reaction. Compared to the traditional processes, this new technology can lower the reaction temperature by 30-50℃, and reduce energy consumption by 20-30 percent, leading to a significant decrease in CO2 emissions.

Multiple national patents have been filed for this new technology, which has progressed beyond laboratory research and entered the industrial scale-up stage. Wide implementation of this technology will promote a greener and more sustainable petrochemical industry, thereby helping China achieve its goals of carbon peaking and carbon neutrality. It will also help make substantial progress towards mitigating climate change and ensure a more sustainable future for our planet.